Unprecedented Bidding War Erupts Over Anysphere, Creator of Popular AI Coding Assistant Cursor

Technology News

Zaker Adham

09 November 2024

26 August 2024

|

Zaker Adham

Summary

Summary

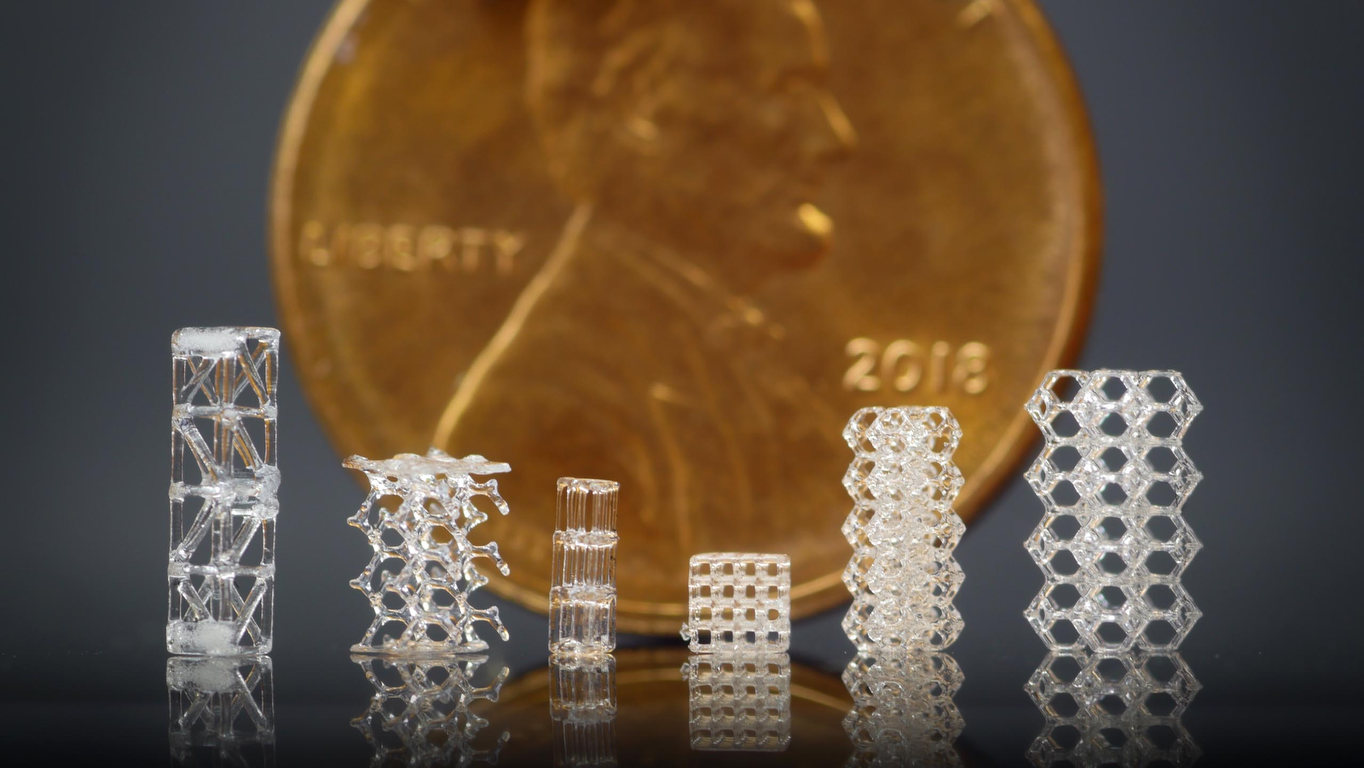

Researchers at the University of Notre Dame have developed a groundbreaking 3D printing method that can precisely deposit glass at a rate of 15 cubic millimeters per second. This innovative approach, which adapts traditional glass-blowing techniques to a robotic platform, has the potential to revolutionize the creation of transparent solid structures used in optical, microfluidic, and photonic devices.

Led by Associate Professor Ed Kinzel from the Department of Aerospace and Mechanical Engineering, the team aimed to combine the geometric freedom of handblown glass with the precision of modern 3D printing technology. Traditional glass shaping methods have long been constrained by the material's high thermal stability, stiffness, optical transparency, and chemical inertness, making it difficult to use in additive manufacturing processes.

The new technique, known as digital glass forming, employs a carbon dioxide laser to locally melt a small-diameter glass filament. The molten glass is then shaped by moving a fused quartz substrate on a 4-axis CNC platform relative to the laser beam. By carefully adjusting factors such as scan rate, laser power, and filament feed rate, the researchers have progressed from slowly printing hollow-tube structures to rapidly creating dense, perfectly transparent 3D solids.

One significant breakthrough in this process is the ability to create bubble-free, fully dense 2D and 3D geometries on a millimeter scale. This advancement holds promise for applications such as lightweight, high-strength lattices that could benefit from the unique properties of glass.

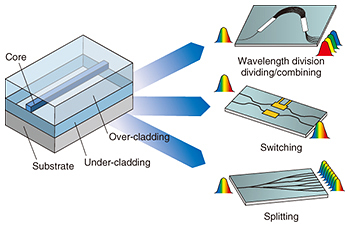

The team has also demonstrated their ability to create optical waveguides, where glass fibers maintain optical transmission around curves. This work lays the groundwork for future developments in photonic circuits, where fibers can be coupled together to transfer light between cores.

This pioneering research was presented at Optica's Advanced Photonics conference in Quebec and further detailed in the Journal of Manufacturing Processes.

Technology News

Zaker Adham

09 November 2024

Technology News

Zaker Adham

09 November 2024

Technology News

Zaker Adham

09 November 2024

Technology News

Zaker Adham

07 November 2024